Precision Optical Systems for Surface Analysis & Inspection

Advanced optical technologies for accurate measurement, profiling, and defect detection across complex material surfaces

Overview

Optical Measurement & Surface Inspection Systems are essential tools in modern engineering, manufacturing, and research applications.

These systems enable non-contact, high-resolution analysis of surface features to detect defects, ensure dimensional accuracy, and support quality assurance across a wide range of materials and components. By leveraging optical technologies, they offer real-time insights into surface conditions without damaging or altering the object being inspected.

At Optical Visual Tech, we offer a comprehensive portfolio of optical inspection systems engineered to optimize operational efficiency, improve product quality, and reduce rework or failure rates. Whether you require in-line machine vision solutions or precision lab-grade surface profilometers, we can provide the expertise and technologies that best suit your environment.

Optical Measurement & Surface Inspection Systems

By combining precision optics, automation, and smart data capture, our systems empower businesses to enforce the highest levels of quality assurance. At Optical Visual Tech, we partner with clients across North America to deliver not just products—but complete solutions customized to their inspection and surface analysis needs. Our team is ready to help you reduce inspection times, minimize production downtime, and elevate your quality control standards.

Advanced Measurement Capabilities

These systems employ various techniques, including laser scanning, structured light projection, and photogrammetry, to capture high-resolution 3D data. They can measure intricate geometries, dimensions, and tolerances with extreme accuracy. Many systems integrate powerful software that provides real-time analysis, allowing for automated defect detection, dimensional validation, and surface roughness analysis. This capability is critical for identifying minute flaws like scratches, dents, and surface irregularities that are invisible to the naked eye.

Our Product Offerings

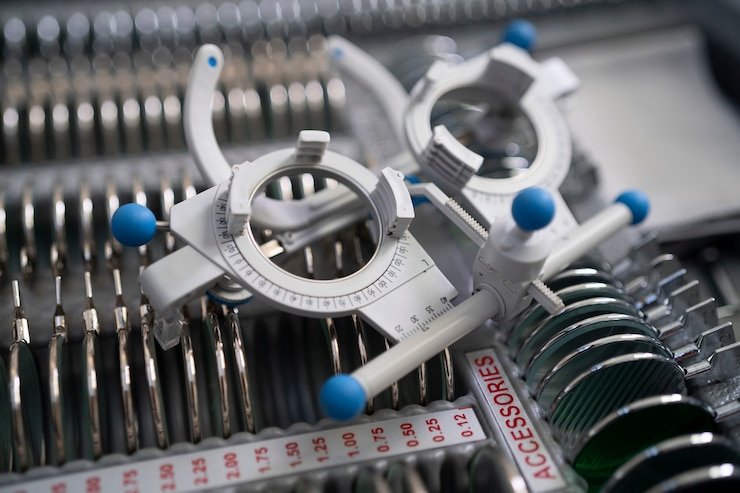

Optical Comparators (Profile Projectors)

Project a magnified silhouette of a part onto a screen for quick and accurate dimensional comparison against reference standards. Ideal for small component inspection and machining accuracy checks.

Laser Surface Profilometers

Utilize laser-based systems to measure surface roughness, waviness, and topography with extreme precision. These systems support R&D, production, and quality assurance applications.

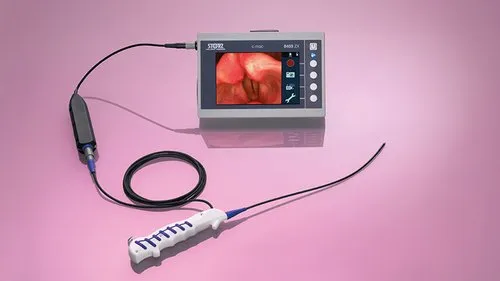

Machine Vision Systems

Integrate seamlessly into automated manufacturing lines to detect surface defects, dimensional inconsistencies, or assembly errors in real time using AI-enhanced vision algorithms.

Infrared & Thermal Imagers

Reveal hidden surface defects or internal inconsistencies by identifying temperature gradients or heat leaks, crucial for electronics, automotive, and aerospace industries.

3D Optical Scanners

Capture complete three-dimensional surface geometries for reverse engineering, dimensional validation, or failure investigation. These scanners support high-speed, highaccuracy workflows across a wide range of part sizes.

Why Choose Optical Visual Tech?

By combining precision optics, automation, and smart data capture, our systems empower businesses to enforce the highest levels of quality assurance.

At Optical Visual Tech, we partner with clients across North America to deliver not just products—but complete solutions customized to their inspection and surface analysis needs. Our team is ready to help you reduce inspection times, minimize production downtime, and elevate your quality control standards.

Ready to enhance your inspection capabilities with precision optical systems? Contact Optical Visual Tech today to speak with our experts, request a quote, or explore customized solutions for your application. We’re here to support your success with responsive service, technical guidance, and scalable technologies.

Looking to upgrade your inspection capabilities or integrate 3D optical scanning into your workflow?

Contact Optical Visual Tech for personalized support, quotes, or technical guidance.Our team is here to help you transform precision scanning into competitive advantage.